A story about the flow approach

The results of the flow approach speak for themselves. At the beginning of a collaboration, our clients often ask for a description of the flow approach, which also speaks for itself.

Our colleague Kevin Fox tells a story which is well suited to this purpose. His story makes the essence of the flow approach visible. Visible like bright blue light. We hope this story inspires you, as it did us.

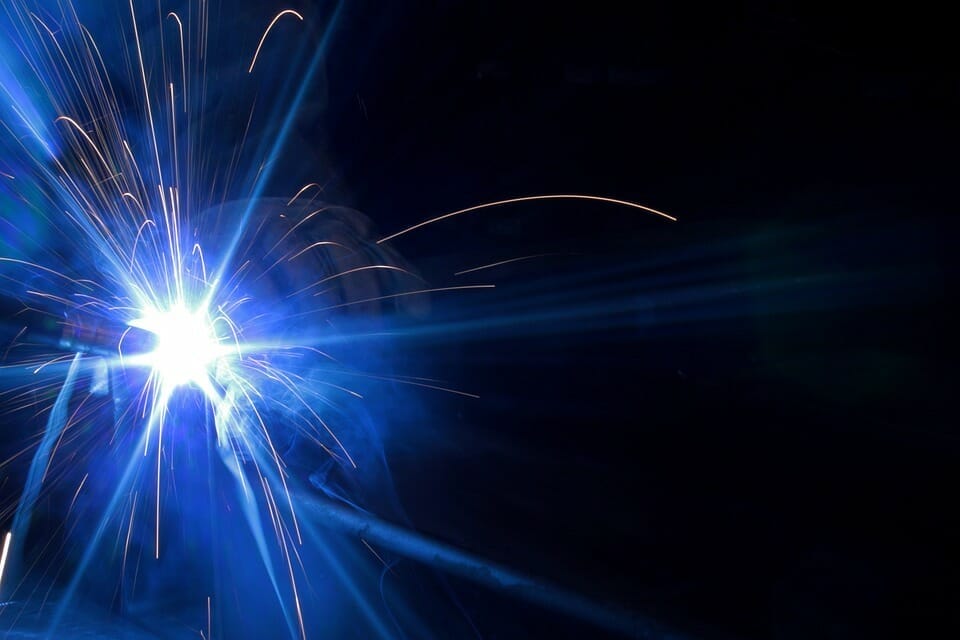

Blue light

Kevin, a young consultant, has been asked by head office to look at a plant, which produces heavy metal bumpers, to see if he can find a solution to their capacity problem.

There are plans to double the number of welding booths at the plant from three to six. Not an easy goal, given the severe shortage of welders in the labour market. When Kevin visits the plant, the plant manager first tells him that the welding department is operating at 93% efficiency. His message is clear: you are wasting your time, there is nothing to improve here, we need extra welders…

Kevin eventually manages to convince the plant manager to have a look at the welding stations together. In doing so, as always, Kevin makes an image of what good looks like. His image is blue light. When the operation is running at maximum capacity, the blue light of the welding torches should be visible all the time. If there is no flickering blue light, the process has come to a standstill.

Kevin and the plant manager stand together for five minutes watching. The first thing they see is a welder turning off his welding torch, taking off his protective gear and walking to his mate in the booth next door. He waits until he gets his attention and his mate also stops and takes off his equipment. Together, they walk back to the first man’s booth and lift the heavy finished bumper off the welding table onto a pallet, then they place a new non-welded bumper from the row onto the welding table.

Then the first welder starts removing the plastic protective layer from the bumper at the places where he needs to weld. He grabs the parts and clamps them on the bumper, puts on his equipment and welds for about 30 seconds. Kevin looks at his watch, we had been there 5 minutes and he had welded for 30 seconds of it.

Another welder comes with a trolley to move the pallet with the finished bumper to the next operation. Then this man disappears with that same trolley to get the parts, which he has to weld on the bumpers, from the warehouse. Meanwhile, the first two welders repeat their bumper-lifting dance.

Kevin estimates that the “blue light time” cannot be more than 10 per cent. Right at that moment, the plant manager turns to him and says something Kevin will never forget: “You see, they are busy all the time!”

Do you see blue light?

This story shows that two people can look at exactly the same thing and see it completely differently. The plant manager looks from the assumption that people need to be constantly busy, while Kevin looks from the perspective of the operation where `blue light’ is an indication of the flow or throughput of that process.

From the plant manager’s point of view, the obvious solution is to hire additional welders and double the number of welding booths. From the point of view of blue light, a much more effective measure is possible, and one that is also more cost-effective. Two assistants are transferred from another department to the welding department and instructed to do everything possible to keep the blue light burning as long as possible. The workers make sure that the materials and bumpers are ready for the welders and that the welded bumpers are put away. Instead of 30 seconds in 5 minutes, welding can now take 30 seconds per minute. A 500% improvement! Without the need for new – scarce – welders.

`Blue light’ is a metaphor for the flow of processes. Project environments differ from production environments as described above. But the principle of flow applies in both situations: like welding on bumpers, work on projects should flow uninterruptedly as much as possible. A project that is stagnant is like a welding booth without blue light.

Can the blue light in your organisation shine longer ?

When you look at your project organisation, do you know which process is the welding department, so to speak, or the bottleneck where the blue light is not burning enough? Or is it rather what we call a “wandering bottleneck”? Where work piles up at a different group each time? Yet only one function can be the true bottleneck function. If you identify this function and organise projects in such a way that this function is neither under- nor overloaded, but can work in a focused way, the organisation will reach its highest possible productivity. If you miss this analysis, your organisation may be working far below its capacity while all staff are fully occupied.

An indication that your organisation can improve is the feeling that your project organisation is a `black box’ from which projects will come out, yet no one can say for sure when.

Your answers to the following questions also give strong indications of improvement potential:

- Do avoidable errors occur in projects?

- Do your people in projects regularly ask what has priority?

Are you wondering if the blue light can shine longer in your organisation? Feel free to get in touch today. We will be happy to help you find the answer.

Willem de Wit, Menno Graaf, Niels Mani, Emmo Meijer, Kerstin Zulechner

December 2022

© copyright 2022 Mobilé 4 flow & innovation