Smartly copying process innovations makes a lot of sense

In the comparison between economic sectors, the productivity of the infrastructure sector has been at the bottom of the list for many years. This is not because of a lack of will power. Our calendars are full of meetings where we talk about innovation. But as a keynote speaker recently said, sometimes you can achieve more with smart copying. After all, there is no point in reinventing the wheel, when the wheel already exists.

In previous blogs we wrote about applications of the concept of the bottleneck in the infrastructure sector. Eliyahu Goldratt introduced the concept into the production environment in his book The Goal. Later, the concept was also applied in logistics and project management. We described applications where the productivity of infrastructure projects increased by more than 20%. The logic is clear. The bottleneck is the limiting factor. If you identify the bottleneck and manage it smartly, you can achieve the biggest possible leap in productivity. Improvements that do not address the bottleneck are a waste of time and effort.

The concept of the bottleneck is an example of a process innovation with clear outcomes: applications often increase output by more than 20%. It therefore makes a lot of sense to copy the concept.

Theory and practice

Readers noted that the bottleneck is a strong concept, asked us however, how to put it into practice. That is our job. Below we describe two cases from praxis.

Case 1

The project office of an infrastructure owner is looking for a solution to a situation where projects repeatedly exceed time budgets by more than a year. This is despite the fact that planners include large time buffers in their plannings, which is, paradoxically, of little help. Managers speak of a planning paradox: despite time buffers, schedules are not met. Further questioning provides the following information. The project office distinguishes between project and process. Process is the planning phase in which scope and end dates can still be subject to changes. In the project phase, the scope and delivery date must be fixed. In practice however, it is often not clear in which phase a project is. How can applying the bottleneck concept improve this situation?

Case 2

A new public transport track is being built. The new track requires adjustments to two adjacent intersections. The plan is poured out over the project organisation. There a conflict arises about who does the traffic lights. Administrative agreements about time and scope appear to be incorrect, and a contractor asks for adjustments. This additional work naturally leads to budget overruns. How could application of the concept of the bottleneck have prevented this?

Nothing is as practical as a good theory

Any system has of necessity one limiting factor: the bottleneck. In the system “bottle”, it is the real bottleneck. If you manage the bottleneck smartly, you can achieve the highest possible output. In the example of the real bottle, the bottle empties four times faster by inserting a straw into the bottleneck and turning the bottle over, than if you just turn the bottle over. And without wild bubbles. Each system has only one or only a very limited number of bottlenecks. “Bottleneck” is, in other words, not synonymous with “problem”. The bottleneck is the limiting factor. By managing it smartly, you often solve many problems in one fell swoop, and increase the output by a quantum leap.

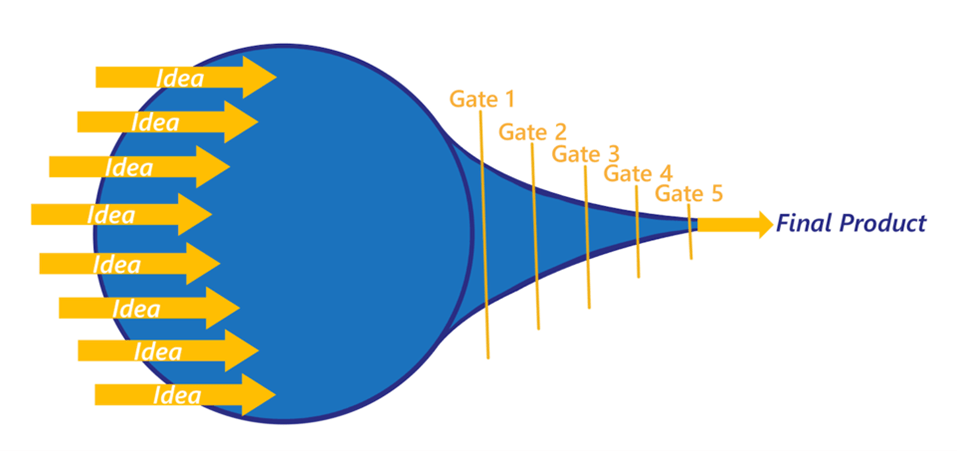

As far as the innovation function of an organisation is concerned, the bottleneck is the stage-gate-funnel. In the stage gate funnel, all stakeholders work together on the best possible solution to a problem. Graphically, it looks like this:

In addition to innovation, the stage gate-funnel is also applicable to the preparation phase of projects. The phase that we have called “process” in case 1. The idea is to agree on clear deliverables for each gate in this process. The problem that the scope of the traffic lights is still negotiable while the project is already in execution can be avoided once and for all by dividing the preparation process into clear phases and to require that predetermined deliverables must be shown to get from one phase to the next. The scope of the traffic lights should have been delivered in one such gate. Without it, the preparation could not have been completed, let alone that the project could have started. Nothing is as practical as a good theory.

In the operational part of a project organisation, most often one function group is the bottleneck. By smartly managing the work of these key employees, for example, by preventing downtime, multitasking, quality-related re-work both the outcome of this bottleneck function group as well as output of the entire organisation will increase by a quantum leap. Smart management of the bottleneck has an effect on the output of the entire organisation and is the first step in the solution of case 1. Schedules as well as due dates will now be met much more often. The second step is to divide the projects that the organization is working on into two categories: innovation or preparation projects on the one hand and execution projects on the other.

The solution to the problem presented in case 1 can now be finished using the following steps:

- Make it clear for each project whether it is a preparation / innovation project or an execution project;

- Manage each project according to the principles for managing either the stage gate-funnel or the resource bottleneck (compare previous blogs);

- Limit the number of preparation projects that people work on, using the principles of the stage gate-process;

- Limit the number of execution projects that people work on in such a way that the bottleneck resource is optimally loaded – not overloaded, not underloaded;

- Make a list of projects that the organisation is actively working on, and do not allow people to work on other projects.

Above measures prevent people from:

- Doing undefined work, of which it is not clear what it entails or to what it contributes;

- Losing time due to multitasking (did you know that by multitasking on two tasks, 1/3 of the available time gets lost?);

- Starting tasks that are unprepared and making mistakes as a result;

- Having to spend time on re-work to correct mistakes.

We are curious about your estimate of how much the productivity of your project organisation could increase by the rules above and its effects. Your estimate is about the increase in productivity that your organisation can achieve with process innovation. If your estimate is higher than the productivity figures you are used to, we would be interested to talk with you about your situation and how to capitalise on this potential.

Process innovations for a quantum leap

The WHY of our work is to contribute to solutions for the major problems of our time, such as energy transition and climate adaptation. As a result of the war in Europe, finding solutions to these challenges has become even more urgent. We learned that Europe cannot afford to be dependent on Russia in any way. Also, climate change will not wait because of the war. On the contrary…

We believe that the thinking and innovation power in the infrastructure sector are highly important to find solutions to the energy transition and climate adaptation. Smart ways to make better use of the bottlenecks leads to acceleration of both the energy transition, climate adaptation and, not to be forgotten, the V&R task. All in all, managing bottlenecks smartly amounts to process innovations and a quantum leap in the productivity of the infrastructure sector, with stronger European infra organisations as an effect and a correspondingly stronger European position on the international stage.

Smartly copying process innovations to get there makes a lot of sense.

Willem de Wit, Menno Graaf, Ian Heptinstall, Hugo van Merrienboer, Emmo Meijer

19th May, 2022

© copyright 2022 Mobilé 4 flow & innovation